Table of Contents

- 1 Applications of 3D Printing in the Medical Field

- 2 Advancements in 3D Printed Medical Implants

- 3 3D Printing in the Automotive Industry

- 4 3D Printing in Aerospace and Defense

- 5 3D Printing in Architecture and Construction

- 6 Eco-friendly Aspects of 3D Printing

- 7 Cost and Time-saving Benefits of 3D Printing

- 8 Current Challenges and Future Possibilities of 3D Printing

- 9 Author

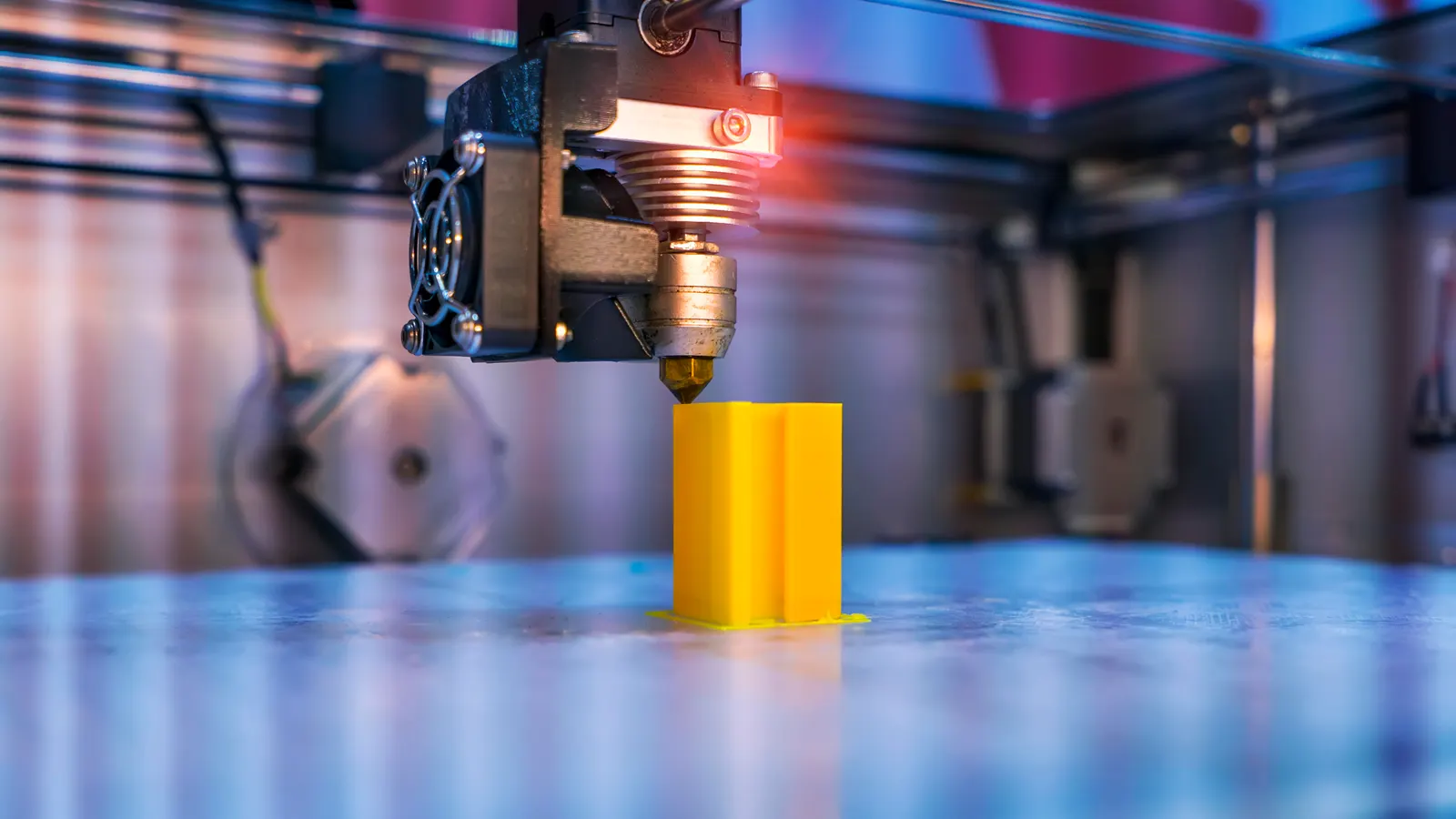

From revolutionizing the medical industry with custom-made implants to constructing sustainable eco-homes, the advancements in 3D printing technology are reshaping our world in incredible ways. This groundbreaking technique, also known as additive manufacturing, allows for the creation of three-dimensional objects by layering successive materials.

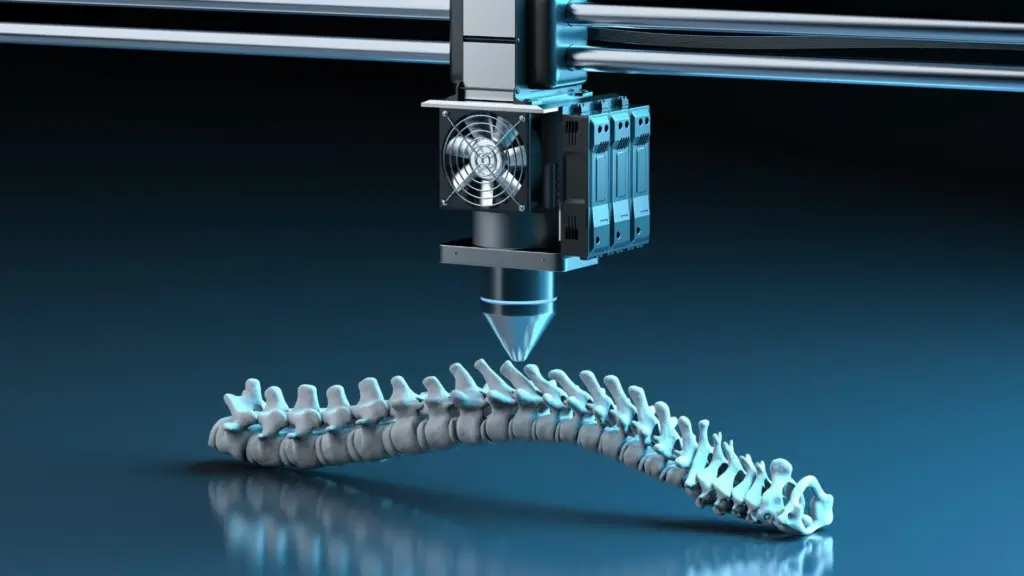

Applications of 3D Printing in the Medical Field

The world of possibilities that opened with the arrival of 3D printing in the medical field is immense. For instance, surgeons can develop patient-specific implants, such as hip replacements or cranial plates. While these implants might fit the patients to whom they’re originally intended, they’re likely disrupting their recovery timeframes.

When utilized, traditional’plates may result in painful complications; but, with 3D printing, doctors may create implants just in the patient, without comparing them to all other aspects of the anatomy. It ensures a higher rate of success and an improved patient experience. Moreover, 3D printing facilities are producing complicated structures like bone scaffolds and organ replicas, which are employed in training and surgery planning. Reproduction of anatomical bones or organs has forever transformed surgical possibilities and outcomes.

Advancements in 3D Printed Medical Implants

The progress achieved in the development of 3D printed medical implants is truly groundbreaking. While traditional implants were limited in size and shape and had to be modified during the surgical procedure, 3D printed alternatives are customized for each patient and designed to fit their needs perfectly. As such, there is no need to correct implants during surgery, which significantly reduces procedure time.

Moreover, the high number of biocompatible materials supports the function of natural tissues, integrating them into the body’s system, reducing the risk of rejection. Finally, making the porous structure in the implants adds to the speed of osseointegration as the volume of open-space available accelerates the speed of healing, improving long-term results. In conclusion, it is safe to say that 3D printed medical implants have a bright future for patients in need of prosthetics.

3D Printing in the Automotive Industry

Not only in the field of medicine does 3D printing has its application; the automotive industry has also been significantly revolutionized by the printing technology. Ranging from prototyping to the production of end-use parts, 3D printing has increased the ease and efficiency with which components are produced, creating preferable alternatives to end-manufactured components. The evolution and development of complex 3D geometries have revolutionized automotive design drastically.

This has, in turn, improved the vehicle’s aerodynamics, reduced weight, and consequently increased performance. Moreover, 3D printing components produced through the technology are less dense and can withstand a high level of stress. The application of ongoing materials and recycling materials creates the innovation that makes the auto industry sustainable.

3D Printing in Aerospace and Defense

In the aerospace and defense sectors, 3D printing has revolutionized manufacturing processes, enabling the production of complex components with reduced weight and increased efficiency. Traditional manufacturing methods often involve multiple steps, including machining and assembly, which can be time-consuming and costly. However, with 3D printing, intricate aerospace parts, such as turbine blades or fuel nozzles, can be produced in a single step, eliminating the need for assembly and reducing material waste. Moreover, 3D printing allows for the creation of lightweight structures, which significantly contribute to fuel savings and improved overall performance. The ability to rapidly produce replacement parts on-demand is also a major advantage in the defense industry, ensuring operational readiness and reducing downtime.

3D Printing in Architecture and Construction

It is not only in healthcare and transportation that 3D printing has brought a lot of changes as it has made several milestones in architecture and construction. Since 3D printing makes it easier to make seemingly complicated shapes and structures, architects can design buildings and structures that were impossible to build in the past. Therefore, 3D printing has facilitated the move into intricate and complex designs that are also sustainable.

3D printing also allows the use of sustainable and recycled materials since the construction process does not generate a lot of waste. Furthermore, 3D printing is useful in areas that suffer from significant housing crises since it is possible to use the technology to build affordable houses more rapidly . These and more are the reasons why there is a bright future for 3D printing in the construction sector.

Eco-friendly Aspects of 3D Printing

Finally, 3D printing is incredibly environmentally friendly. Conventional manufacturing based on removing material generates a lot of waste simply because it is impossible to use all the excess material after production. However, 3D printing inherently allows for precise use of materials, reducing waste and the manufacturing carbon footprint. At the same time, products can also be printed from reusable and biodegradable materials, helping to build a cleaner future.

Finally, producing things on-demand reduces the number of items that must be mass-produced and shipped from afar. Such production is a large consumer of energy and emits a massive amount of carbon dioxide when shipping final products. Therefore, as environmental awareness increases, 3D printing will become a more sustainable solution with jpslot.

Cost and Time-saving Benefits of 3D Printing

In addition to the abovementioned, another notable advantage of 3D printing is its cost and time effectiveness. As established above, conventional ways of manufacturing typically require costly tooling and molds. This hinders the creation of small quantities and customized products and has a detrimental impact on the price-quality ratio. 3D printing, however, does not require expensive tooling, which limits the upfront costs.

Moreover, it also offers a possibility to create a prototype of a product to test it . This enables designers to experiment with different variations without having to go through the manufacturing process repeatedly. Consequently, the time-to-market is reduced, which can increase one’s competitiveness in the market.

Current Challenges and Future Possibilities of 3D Printing

While the potential of 3D printing is seemingly limitless, there are still some challenges that need to be addressed. One of the main issues is limited capabilities in terms of the range of materials that can be used for 3D printing. Although much progress has been achieved in the recent years, the range of potential materials remains quite limited compared to conventional manufacturing. Moreover, 3D printers are currently quite slow, which may pose an issue in mass production.

Nonetheless, researchers and engineers are constantly working to overcome these issues, and it seems they will soon find a solution. Future possibilities are numerous, from creating new materials to improving printing speed. The future of 3D printing seems very promising, and the technology will most likely revolutionize many industries and change the way we design, build, and create. In conclusion, the technological advancements in the field of 3D printing have already had a large impact on the world. The technology has changed medicine through the ability to cheaply and safely produce custom implants.

Moreover, 3D printing allowed to manufacture many structures that are otherwise impossible to produce. Since the technology also allows producing minimum waste, 3D printing is also environmentally friendly. The technology of the future has already happened, and it is only a matter of time before we see even more complex structures produce quicker and with less waste.

Also read: Mata Panda: Solusi Efektif untuk Penampilan Lebih Segar